Three Wire Spiral Projects

For these projects, 14 gauge wire is recommended, but 16 gauge can be

used. Copper, brass, and sterling silver cmust be annealed (heated with a torch) before working.

Copper is recommended because it is easier to work than the

others, is less expensive, and is readily available in hardware stores or as

recycled electrical wire.

Black mild steel is another good choice. It has already

been annealed. It is stiffer

and a bit harder to work than copper, but it holds its shape better than the other metals and is inexpensive.

It is sold in hardware stores as "baling wire" or "tie wire", usually in coils

about six inches in diameter that are wrapped in oiled paper.

Only new steel wire should be used. Recycled steel wire has been unevenly

work-hardened and is often damaged or rusty.

TOOLS: Round nose and chain nose pliers, wire cutters, file, ruler.

For

nonferrous metals: torch for annealing copper, brass, and silver wire.

Dremel, Foredom, or bench grinder with felt or fabric buff and jeweler's rouge.

For black steel wire: Dremel or

Foredom tool with wire brush.

A NOTE ON BUYING PLIERS: Pliers must be purchased from a supplier that

specializes in jewelry and/or metalworking tools.

Many brands and sizes are available. Price is usually (but not always) an

indicator of quality. For the projects described here,

the delicate pliers that are used for gold and silver wirewrapping or for

intricate copper beaded wire jewelry (usually with 18 or 20 gauge wire)

will probably be too small. A slightly larger and sturdier size will be

needed, especially for black steel wire, which is harder than copper

and causes more wear on the pliers. In general, AVOID pliers that cost

less than $10, those that are sold only in sets,

and those recommended by a company or workshop instructor who promotes a

particular brand of tools.

Pliers can cost as much as $50 but you can get good ones for $15-$30 each.

Kent's Tools has a huge selection of jewelry tools. They

sell by mail order but also have a store in Tucson, AZ and a booth at the annual

Tucson Gem and Mineral shows in February.

http://www.kentstools.com/

ANNEALING NONFERROUS WIRE: Use the torch with a large, brushy flame to

heat the wire until it turns black.

Keep the flame moving so you don't overheat parts of the wire. If the

metal begins to glow red, remove the flame! Let the annealed wire cool.

To remove the black firescale (copper oxides), put the wire in a glass bowl of

vinegar for several hours. Set it outdoors to minimize fumes.

When the color is restored, rinse the wire in cold water and let it dry.

It won't be shiny but you'll fix that later.

(This step, called pickling, is often done hot but is safer and just as

effective when done cold. Jewelers traditionally use sulfuric acid which

is expensive, toxic, and unnecessary.)

A NOTE ON TECHNIQUE: These three projects are not intended to offer a

complete introduction to wireworking.

Some experience is helpful but not essential, and the wire clasps are an

excellent beginner's project.

Good wirework is tightly coiled, neatly made, and consistent. These

characteristics form much of the of the aesthetic appeal of wirework. They

also demonstrate skill and good crafstmanship.

Wire ends should be filed smooth, any nicks or rough spots should be sanded, and

the finished item should be polished appropriately.

Earrings present a special challenge, since the designs should be mirror images

(spirals coil in the opposite direction).

If the earrings are intended to be odd, it should be obvious (different lengths,

degrees of complexity, etc.)

I don't use or recommend jigs (pegs, nails in a board, or other

wirewrapping templates) for forming wire. They invariably result in wire

objects that are too open, unstable, and unevenly coiled.

1. Double Spiral

Known from European bronze "spectacle fibula" artifacts

from about 1000 B.C., this versatile motif can be used for most types of

jewelry.

14 or 16 gauge wire can be used, but the larger size is recommended since the

design is most stable and effective in 14 gauge.

The photo above shows a five-coil fibula in 14 gauge copper, and above it a belt

buckle in heavy 12 gauge copper,

which is the largest size that can be worked cold with the tools and techniques

shown here.

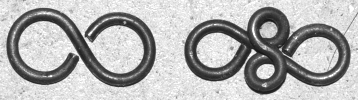

This double spiral is a more elaborate version of the basic figure-eight

chain link:

MAKE A SPECTACLE FIBULA:

Below are finished brooches in 14 gauge copper and 16 gauge black steel.

Note the difference in size even though both have five coils.

Photographed upside down to show the pin and clasp.

1. Cut a piece of 14 gauge wire about 40 cm long. Use round nose pliers

to make two opposite loops at the center of the wire.

The "tails" should curl in opposite directions but both should lie on the top of

the center of the wire, like this:

2. Measure 15 cm from each loop and bend the wire down at a sharp right

angle, perpendicular

to the loops. These "tails" will form the brooch clasp.

3. Use the round nose pliers to start the spiral. Make a tight loop

just above the bend that forms the tail, and form the coil in an S-curve back

toward the central loop.

4. Use the round nose or chain nose pliers to finish a tight coil that

meets the central loops.

5. Repeat with the other half of the wire. Now the spirals are done

and two long wire tails hang from the underside.

6. Clip one of the tails to about 1 cm and file the end smooth. It

can be hammered slightly flat if you wish. Curl it into a "C" to form the

clasp.

7. To form the pin, bend the other tail down so it is close to the brooch

and fits the clasp. Clip it about .5 cm past the clasp, so it doesn't

show from the top.

8. Unhook the pin from the clasp and file the end to form a point.

Fasten the pin.

9. Polish the finished fibula. Use jeweler's rouge on a felt or

fabric buff for nonferrous metals, and a tiny wire disc brush for black steel

wire.

VARIATONS:

1. CENTER LOOPS: The two small center

loops can be wrapped one, two, or three times. Any more and the design

evolves into something different,

like this example with the center loops wrapped four times and finished with

four-coil spirals:

2. WIRE TAILS:

The wire "tails" can easily be finished for chain links and other

jewelry. Many are easier to make than the brooch.

This hairpin is one of the simplest examples. The wires

are shaped, flattened slightly to stiffen them, and the points filed smooth and

round:

3. SPIRAL SIZE

The spirals can be made in several sizes depending on the number of coils.

The design is most stable and durable with three to five coils.

Six or seven coils can be used but the design is less stable (more likely to

bend or unravel with use).

I made a set of reference wires for easy measuring. Sizes and a photo are given below.

These are guidelines only.

For best results with your own projects, make your own set: Coil a scrap

piece of wire the desired number of times, then uncoil and label it.

These are especially useful for production work or expensive materials such as

silver wire.

Note that the number of wraps on the center spiral makes no difference since

they are formed before the larger spirals are measured.

14 gauge wire

5 coils: 15 cm

4 coils: 10 cm

3 coils: 5.5 cm

16 gauge wire

5 coils: 11.3 cm

4 coils: 7.5 cm

3 coils: 4.3 cm

Below is a set of mirror-image chains made from 14 gauge black steel wire links

in three graduated sizes.

Note that the number of wraps on the center spiral also changes (one, two, and

three wraps), but they don't have to be made this way.

All three sizes could have been made with a single central wrap, which would

have made them more compact.

The upper chain shows the top side and the lower one shows the underside so you

can see how it is put together.

The small extra link in the center is made from 16 gauge wire as a size

comparison.

LINK BRACELET in 14 gauge wire uses two types of figure-eight links to set off the

double spiral; the

small links have the center portion flattened before curling.

MAGICIAN'S DOUBLE LEMNISCATE RING was made from a single piece of 16-gauge steel wire.

The wires were curved around a piece of tubing and crossed opposite the

center of the spiral, then wrapped around each other, cut to the desired length,

and finished with a small coil at each side.

2. Triskele and Pinwheel Flower: Spirals with Three or Five Hooks

These were designed as earrings but could be added to other jewelry.

Earrings should be mirror images (the spirals coil in opposite directions, not

both the same way).

Shown below: threefold (triskele) earrings in 14 gauge recycled copper,

single triskele in 16 gauge brass, fivefold spiral in 16 gauge brass.

The threefold version

is the easiest to make and should be tried before attempting the fivefold

pattern.

1. Cut a piece of wire about 30 cm long and make a tight U-shaped bend

about 6 cm from one end.

2. Use the round nosed pliers to coil the bend into a flat loop.

3. Take the wire on the inside of the loop, measure about 2 cm from the

end of the loop, and make another tight U-shaped bend.

4. Form the second U-shaped bend into another flat loop identical to the first one. Measure another 2 cm of wire and repeat.

5. Note that you have two wire "tails" trailing from the finished triskele.

One runs from the outside of a loop, and the other runs in the

opposite direction from the inside of a loop.

One of these will become the central spiral and the other will become the

pendant bail or the loop for attaching a bead and/or earwire. You can

choose which is which.

On the finished examples above, the copper triskeles use the outside wire for

the central spiral, which coils in the opposite direction from the loops.

The brass triskele uses the inside wire for the central spiral, and it coils in

the same direction as the loops.

The fivefold pinwheel uses the outside wire in a spiral that coils in the same

direction as the loops.

6. The fivefold pinwheel design is made the same way as

the triskele, but only about half as much wire (about 1 cm) is measured off for

each loop.

This is a tighter design which will probably need minor adjustments to even out

the loops once it's finished.

3. Fancy Hook and Eye Clasps

These are made in pairs and can take the place of buttons on clothing or bags. They can also be

used as clasps for chain bracelets.

Shown below: a clasp in 16 gauge brass wire, showing the hook (left), the

eye (right).

Copper and brass are recommended for use on clothing. Black steel wire can rust when the fabric gets wet.

Clasps can be worked in three gauges of wire:

14 gauge: Coats, vests, belts, canvas and leather items.

16 gauge: Shirts, sleeves, dresses.

18 gauge: Undergarments, doll clothing, small pouches, etc.

1. Cut two pieces of wire about 30 cm long. On the first one,

form a U-shaped bend in the center and coil it into a loop (not flat as in the

previous project, but hook-shaped).

On the second wire, form a flat loop in the center.

2. Form two tight S-curved flat loops on each wire as shown. These

have a dual purpose: they keep the clasp flat, and they provide four

attachment points for stitching it on securely.

3. Clip the ends of the wire to your desired length for forming the

spirals. If you want all the spirals to be the same size, all wires must

be the same length, as in the example above.

4. Form the spirals. The hook and eye portions may need a bit of

shaping to fit your specific project; check this before stitching them on.

My embroidered shirt made with 16 gauge brass clasps:

http://www.flickr.com/photos/leonfangs/6761124753/

My embroidered vest made with 14 gauge copper clasps:

http://www.flickr.com/photos/leonfangs/6436812007/

IRONWING TUTORIALS by Lorena Babcock Moore

These free online tutorials are presented for entertainment, inspiration, and personal

instruction. All photos and instructions were created by Lorena Babcock Moore.

The photos and instructions are free of copyright, but

credit and a link are

polite, professional, and appreciated.

Content is not intended for commercial use such as publications, classes that

charge a fee, or other for-profit enterprises.

The metalwork designs are not copyrighted. They are

classic

designs found in several cultures and time periods.

Users are responsible for their own safety, tools and materials,

working environment and conditions, and outcome of finished projects.

For best results, read the instructions carefully several times before starting

a project.

I do not claim that my methods are "correct" or that my

designs are "authentic" for a particular culture or time period.

The projects

are not intended for children. I do not teach classes and am not available for

online instruction or advice.